- Home

- Products

- Sock Knitting Machines

- Double Cylinder Sock Knitting Machine

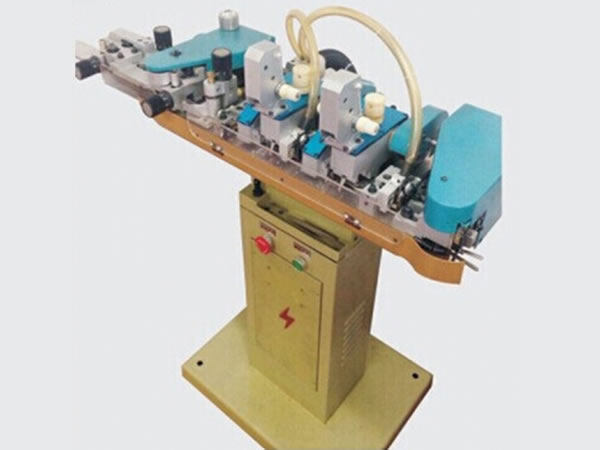

Double Cylinder Sock Knitting Machine

We produce the double cylinder sock knitting machine in 3 different dimensions to meet various customer requirements. We can also offer personalized solutions such as programming the language to your native language, and adding your company's logo to the operating system's display.

The double cylinder sock knitting machine is equipped with a 6 color yarn changing device that is capable of knitting Y-heels, socks for any person: adult or child, man or woman, and rib sticth socks. With a 2 line feeder, the sock knitting machine can knit 3 or 6 different colored yarns. It is easy to maintain, operates in a stable manner, and has an outstanding production efficiency.

This sock knitting machine uses the latest technology in a color screen system that supports multiple language, and features a 1G memory module to story thousands of patterns. The speed reaches 330 revolutions per minute, and only takes about 5 minutes to produce a single pair of socks.

This sock machine is equipped with an automatic alarm system, which can display needle breakage, yarn breakage, needle tip breakage and electronic failures to easily find and fix any problem that may arise. With a "continue after interruption" feature, the machine will maintain the knitting position even if a sudden loss of power occurs.

Features

1. Fully electronic control weaving system, with no roller.

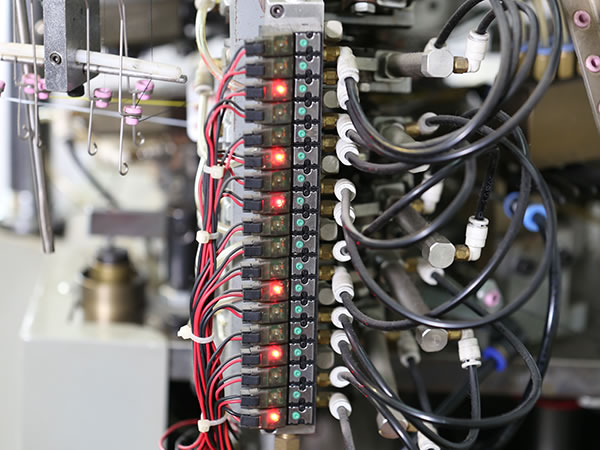

2. The electronic control system is responsible for changing shuttles and pins.

3. The servo motor drives the knitting machine, and regulates the stepless speed.

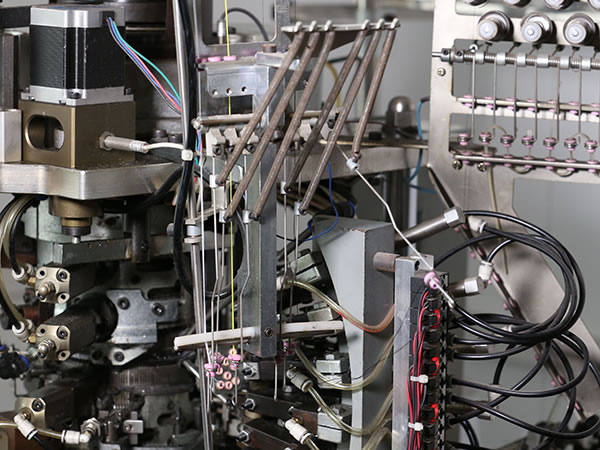

4. Two yarn feeders operate 9 shuttles and 2 sets of scissors.

5. The shuttles are capable of knitting socks in up to 6 colors.

6. Password protection avoids inadvertent changes or modifications, improving the reliability and safety of the sock knitting machine.

7. An automatic alarm system warns of needle breakage, needle tip breakage, yarn breakage, and electronic shutdown. With a "continue after interruption" function, the machine will maintain the knitting position in the event of sudden power loss. When power is restored, the machine will resume knitting where it left off, avoiding loss and waste.

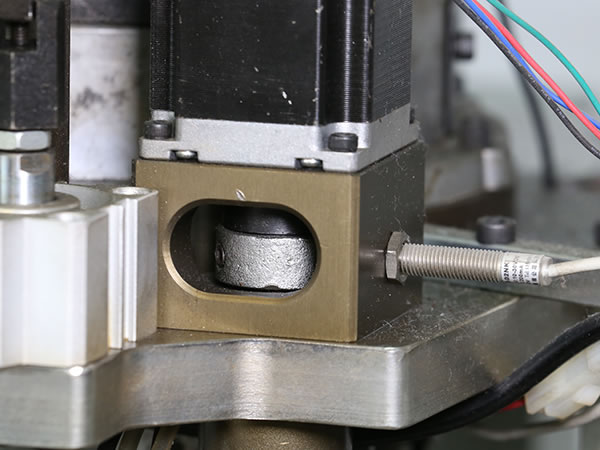

8. The yarn tension and weaving density are carried out using a stepping motor.

9. A sensor is able to automatically protect the machine, and minimize damage in the event of a breakdown.

10. The high speed operation improves the inner cam.

11. The line leading shuttle and cam switch are electro-pneumatically controlled.

12. The knitting machine features an automatic oil feeder system.

13. The yarn changing unit supports up to 6 colors.

14. A Y shaped heel is avaialbe.

15. Equipping the machine with a UPS system commits the current program and knitting action to memory, keeping it set even when there is no power to the machine.

16. Available in 220V/380V/415V and 50/60 Hz.

Uses can choose their own sock sizes, or ask us for help.

A 4 inch double cylinder sock machine is capable of producing the double cylinder socks.

Technical Specifications:

Cylinder Diameter: 4" 4.5'' 5'

Number of Needles: 76-200N

Rotation: 280-300(Max 400)

Production Capacity: 280 pairs/ 24 hours

Servo Motor: 1.5KW

Fan Motor: 0.75W

Control Box: 0.55W

Net Weight: 300KG

Gross Weight: 430KG

Packing Specification (W x L x H): 1020 x 920 x 1900mm, 18/36 SETS 20GP/40HQ